Source: unsplash.com

3D printing (3DP) is quickly becoming a mainstream manufacturing option. At the same time, it’s a rapidly evolving technology capable of a diverse range of applications across industries and customer profiles. According to a PwC survey, roughly two-thirds of US manufacturers are adopting 3D printing in some way or the other and over half are deploying the technology for prototyping and final-products.

With such a dynamic space, it’s worth analyzing what it might offer to manufacturers and consumers alike in the coming years. Here are some future trends for the 3D printing industry.

1. 3D Printing Is Likely to Get Faster and Cheaper

Technologies within the 3D printing ecosystem are developing quickly. The printers themselves are getting both bigger and smaller. It’s now a fairly straightforward process to build prefabricated houses in a matter of weeks, while personal-use 3D printers have begun to make an appearance for individual innovators.

All of this, while the cost of production and ownership of 3D printing has gone down. 3D printers have long seen their prices being slashed. However, the same is now true for 3D scanners. Instead of having to costly outsourcing of design and modeling, they can now vertically integrate by performing those functions in-house.

Machines can also handle a greater variety of materials, including ceramic, metal powders, and glass, helping with costs as well as speed of diversification across new industries. The 3DP industry is expected to sustain and accelerate these trends over the coming years.

2. It Will Transform Supply Chain Processes

3D printing has been touted as a solution to the supply chain crises sweeping the world. The technology offers a decentralized manufacturing model where machines can be positioned closer to the customer and reduce the role of shipping and transportation services.

Typically, the weak link in any supply chain is inventory. Traditional manufacturers often prefer large orders to cover their development and overhead costs, which smaller customers can’t always afford. And if they produce excess stock, it tends to run up their storage and inventory expenses, which adds to the cost of purchase for the buyer.

3DP offers an on-demand solution that can be “switched on and off” at will. It reduces prototyping costs and practically eliminates extended inventory costs. As a result, 3DP is quickly becoming an integral part of supply chains worldwide across industries.

3. Automation Will Become a Key Focus

One of the aspects of 3D printing that can lag behind conventional manufacturing is the speed of mass-produced products, especially ones with fairly simplistic designs. Where additive manufacturing excels is with small-batch production, where it can often guarantee faster output than, say, injection molding or CNC machining.

Automation is one way to remedy this imbalance. Improved software and more versatile machine printers have helped significantly reduce production timeframes, allowing companies to get to market quicker. Automation can also help mechanize a host of post-processing tasks which are still executed manually and improve delivery time.

4. Bioprinting Will Become Mainstream

Source: pexels.com

One of the leading — and somewhat unexpected — applications of 3DP has been in the healthcare space. Bioprinting, in particular, has proved to be revolutionary for patients and medical teams worldwide. Bioprinting is a process that uses cells and/or biomaterials to create organic parts that often emulate natural tissue characteristics.

Scientists and medical researchers have used this process to recreate natural body parts, including tissue, bones, blood vessels, and even entire organs. Bioprinting is already used widely to create parts for pharmaceutical development, drug validation, and medical academia. It could conceivably be used to create live human organs at some point, perhaps replacing the need for organ donations and transplants.

3D Printers Will Become Consumerized

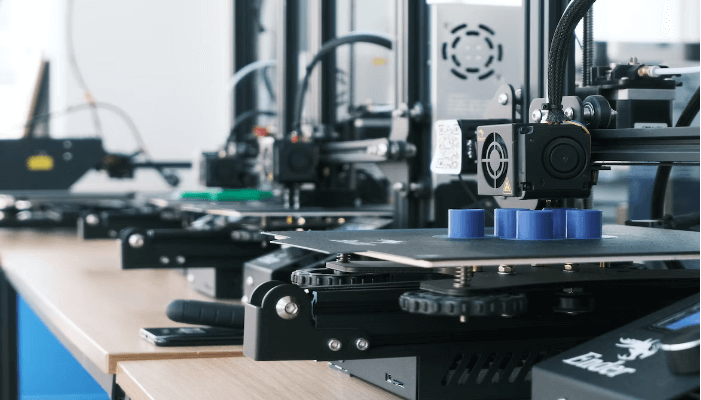

Desktop 3D printers are already fairly common, particularly at laboratories and innovation centers. These can help churn out a small run of products in a matter of days, compared to the weeks and months it would take for a conventional supplier to do it.

Also Read: Top 10 Best Technologies That Were Invented In The 2000s

The day isn’t far when most consumers will have a 3D printer of their own at home. It will play a similar role to that of a food processor or ink printers by allowing people to create items they would normally have to buy. Personal 3D printers could conceivably be used to produce anything from small containers to carry bags, home improvement products, tools, precision components, and more, based on downloadable “recipes.” This could potentially revolutionize how people consume products and services.

As it evolves, 3D printing will continue to surprise and facilitate manufacturers and consumers alike. With the progress on feed materials, its applications could potentially be limitless and have deep seated impacts on consumption patterns and business processes worldwide.